Common stainless steel 304, 304L, 316 and 316L in the valve field

- Mar 07, 2019

- Hits: 9

The difference between the common stainless steel 304, 304L, 316 and 316L Stainless steel valves are usually used in applications where the working medium has certain corrosive properties. The steel used...

Selection of valve materials for several acidic media

- Mar 02, 2019

- Hits: 2

t: Selection of valve materials for several acidic media k: Chemical Valves, Stainless Steel Valves, Pump Valves, Valve Material Selection, Fluorine-Lined Valve, Rubber-Lined Valves, Plastic Lined...

Common non-destructive testing methods for forged steel valves

- Mar 02, 2019

- Hits: 3

Some valves require non-destructive testing for special conditions, including but not limited to forged steel valves. Here are some tips for nondestructive testing. NDT is an abbreviation for Non-destructive...

Factors affecting quenching crack or heat treatment crack

- Mar 01, 2019

- Hits: 3

Factors affecting quenching crack There are many factors affecting the quenching crack. Here, only a few cases that are often encountered in production are introduced. 1. Quenching crack caused by defects...

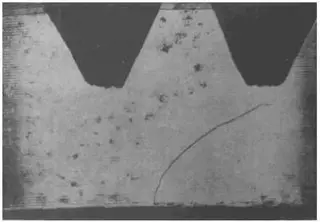

Brief analysis on forging crack and heat treatment crack

- Mar 01, 2019

- Hits: 5

Forging crack Forging cracks are generally formed at high temperatures. During forging deformation, the cracks expand and contact with air. Therefore, under the microscope of 100X or 500X, the cracks...

The purpose of forging and causes of forging cracks

- Feb 28, 2019

- Hits: 3

First of all, it is necessary to define the concept of "raw material crack" and "forging crack". For cracks appearing after forging, it should be understood as "forging crack"....

The material selection of forged steel low temperature globe valves

- Feb 28, 2019

- Hits: 7

The characteristics and structure material selection of forged steel low temperature globe valves First, the design of the low temperature valves The design of the cryogenic valve has the following requirements,...

3 Points worthy of notice on pipeline valve installation-part one

- Feb 14, 2019

- Hits: 1

First, cautiously check before valve installation. 1. Carefully check whether the model and specifications of the forged steel valve meet the drawing requirements. 2. Check the valve stem and disc opening...

3 Points worthy of notice on pipeline valve installation-part two

- Feb 14, 2019

- Hits: 4

Third, pay attention to the following small details. 1. The valve body of the forged steel valve is mostly made of cast iron, which is brittle and therefore must not be hit by heavy objects. 2. When...

Points worthy of notice on forged steel valve operation-part two

- Feb 14, 2019

- Hits: 5

Some media tend to cool after the forged valve is closed, so that the valve parts are shortened. Therefore, the operator should close the forged valve again at the right time, so that there is no gap...

Points worthy of notice on forged steel valve operation-part one

- Feb 14, 2019

- Hits: 5

Regarding the forged valve, it is necessary not only to install and protect, but also to operate. (1) The opening and closing of manually-operated valves. A manually-operated valve is the most widely...

Forged valve installation and maintenance methods-part two

- Feb 12, 2019

- Hits: 4

2. Field operation Care must be taken during installation and construction. Do not hit the valve made of brittle material. Before installation, the forged valves should be inspected one by one, check...