Key Specifications / Features

Model No.: FTBV-20250402-07 Hits: 19

As a leading forged trunnion ball valve supplier in China, we provide high-performance valves designed to meet ASME B16.34, API 608, and API 6D standards. Available in sizes from 1/2 NPS to 24 NPS, with pressure ratings from Class 150 LB to 2500 LB, our valves offer versatile connection options, including socket weld, butt welding, and flanged ends. Built for reliability and durability, these trunnion ball valves ensure tight sealing, low operating torque, and exceptional performance in demanding industrial applications. Trust us for superior quality and long-lasting service.

Request a quoteTags

Detail Information

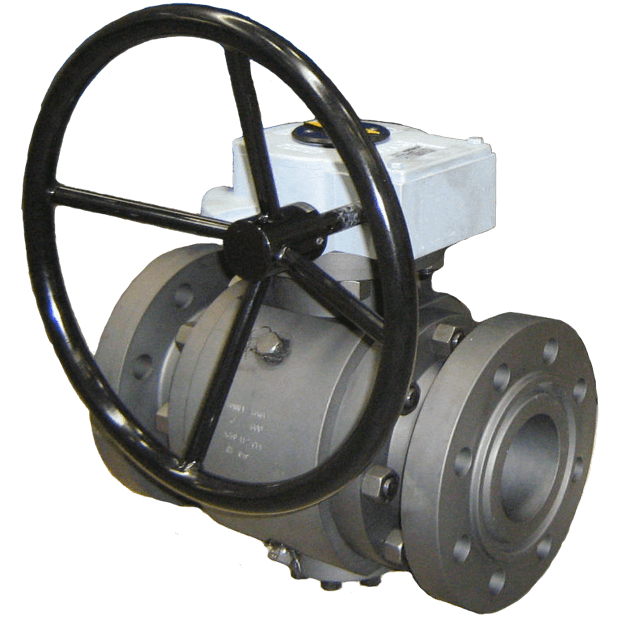

Product Name: Forged Steel Trunnion Ball Valve

Design Standard: ASME B16.34, API 608, API 6D

Size Range: 1/2 Inch - 24 Inch

Pressure Range: Class 150 LB - 2500 LB

Inspection & Testing: API 598

Marking: MSS SP-25

Fugitive Emission: ISO 15848

Face to Face: ASME B16.10

Socket Weld: ASME B16.11

Screwed Ends (NPT): ASME B1.20.1

Flanged Ends: ASME B16.5

Butt Welding Ends: ASME B16.25

Product Features:

1. Standard Double Block Sealing: Ensures reliable isolation and leak prevention for enhanced safety and performance.

2. Fully Forged Construction: All pressure-containing components are manufactured with a full die-forged structure, delivering superior strength and durability.

3. Integral Flanged Design: Flanged valves are designed with an integral closure member, providing robust connections and structural integrity.

4. Advanced Sealing Solutions: The standard primary gasket features an OR AED-type design, while a secondary emergency seal offers fire-safe protection.

5. High-Quality Packing: Ensures reliable tightness and low-emission performance, meeting stringent industry standards.

6. Optimized Sealing and Durability: Low-friction seat and ball materials, along with precision surface finishes, provide dependable sealing and extended service life.

7. Industry-Leading Cv Values: Delivers exceptional flow efficiency and precise control.

8. Reliable Body-Closure Connection: Standard split and bolted design ensures secure and leak-proof body-closure connections.

9. Low Operating Torque: Engineered for smooth operation and reduced effort during valve actuation.

10. Anti-Static Device: A static conduction spring between the stem and ball ensures reliable grounding, preventing static discharge.

11. Anti Blow-Out Proof Stem: Robust design prevents stem ejection, enhancing safety and reliability.